Bakery

Dough, Pan, Proofing, Cooling, Freezing or Packaging; we have a belt for your Application.

Dough, Pan, Proofing, Cooling, Freezing or Packaging; we have a belt for your Application.

Contact us with your concerns about Cleaning, Draining or Temperature Variations during transport, we can help select the correct belt.

Whether Salmon, Shrimp or Mussels are your product we have a Duralink belt for your specific application.

Concerns with cleaning, draining or freezing applications for your Meat and Poultry? Let us help you select the correct Belt.

Contact us for specific solutions for your Receiving , Pasteurizing, Blanching, Freezing or Packaging requirements.

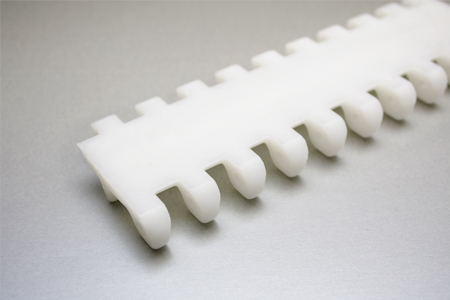

Open, flat top, perforated flat top or raised rib to help successfully package and transport your product.

Duralink will be attending the North Atlantic Fish and Workboat Show 2016 at Mile One Centre in St. John's, NL from November 18-19, 2016. Come by and...

Duralink will be attending the Seafood Expo North America 2016 in Boston, MA from March 6 - 8, 2016...

Duralink and P.B.A. Industrial Supplies Ltd are excited to announce the launch of our newly designed website...

Industry leading features are great but whats more important is how each feature benefits you. Simply put, Duralink offers industries the best combination of features and benefits.

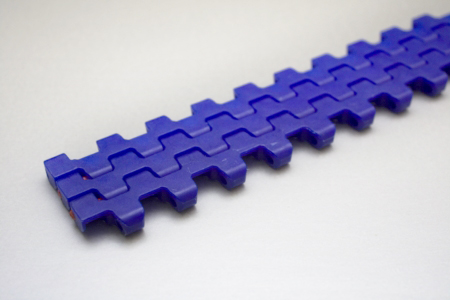

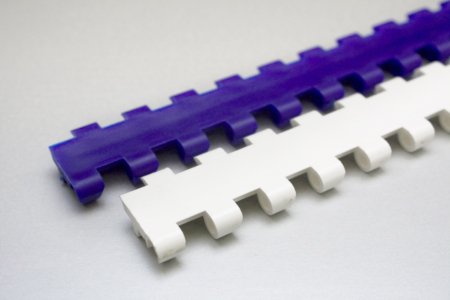

Plastic modular belting has a long proven history of out lasting conventional rubber belts. Furthermore, unlike rubber belts, damaged sections can be repaired or replaced in minutes with very low material cost.

Modular belting far out performs conventional rubber in weight carrying and conveying capacity. The brick like assembly pattern and sprocket drive assemblies ensure belts can handle even the most demanding application.

A wide variety of module styles include numerous open areas and fully cleanable hinge designs. Depending on the application, our products can be manufactured to exceed FDA and CFIA requirements for your food contact applications.

There are over 30 belting styles designed to operate in a wide range of applications and temperatures. Regardless of whether you are cooking seafood or freezing pastries we have a belt to meet the task. Call our application engineers to help with the correct selection.

Modular belting simply lowers plant operating cost by lasting longer than conventional belts and reducing the maintenance cost associated to replacement. As well, they reduce production downtime required for repair or replacement.

Duralink has completely changed our production capacity. It allows us to easily drain our product efficiently while eliminating product damage and is now used throughout our entire process.